Basic characteristicss and advantages of the drying plant for fruits and vegetables ACM-2000 are:

1. A heat recovery system

Drying plant ACM-2000 operates in a isolated system in which preheated and filtered air circulates by which:

- contamination of raw material with impurities is prevented and certificates of the most rigorous global standards regarding the quality of the dry product are provided;

- most of natural taste and smell of fruits is retained leading to a dry product of top quality;

- unlike open systems, the heat energy is recovered and returned to the process.

2. Universality

By controlling drying parameters – temperature, humidity and air circulation rate- technological conditions in compliance with the required parameters of drying kinetics of many kinds of fruits, vegetables, forest fruits and medical herbs may be provided. Capacity of ACM dryer can range from 500 to 5000 kg based on plum.

3. Stepwise drying

Tube finned heaters are mounted from top to bottom on both sides of every chamber providing uniform distribution of temperatures inside the dryer. All the trays are in equal temperature condition enabling uniform drying of the material. By stepwise drying and moderate air circulation rate the most favourable drying curves and the best performance of the dryer can be achieved.

4. Low temperature drying

Dry, warm air is ideal for drying but only if air temperature is strictly controlled. In the dryer of ACM type biomaterial is dried at low temperatures (max. T=53-60°C) and low humidiy (RH= 20-25%). Poor quality of the dried product is always a result of high temperature, which cannot occur in this dryer. In the dryer ACM-2000 air capacity to receive moisture is increased by reducing humidity compared to conventional convective dryer where the air temperature is increased.

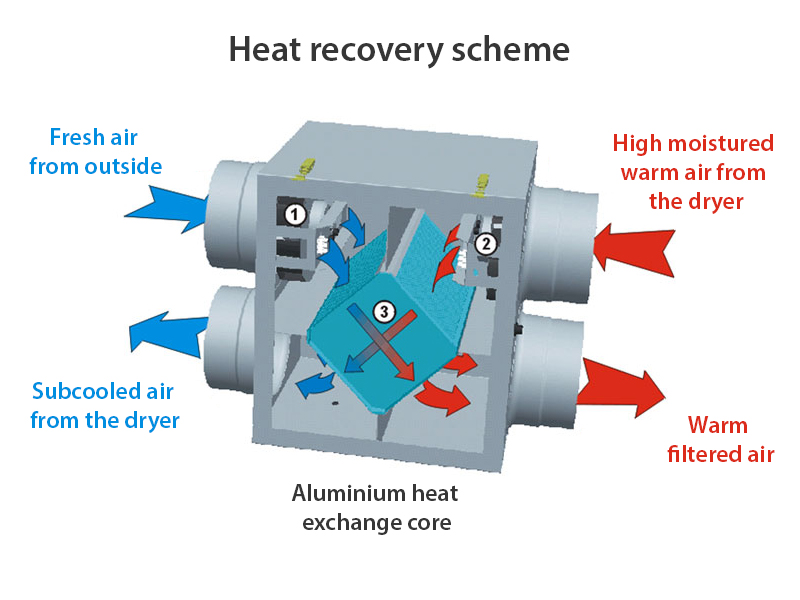

Double heat recovery system

The dryer ACM-2000 is equipped with a special air recovery system with many functions. The moisture released from the fruits and vegetables is taken by the air circulating the dryer. This air saturated with the moisture should be vented to the atmosphere. First recovery system is a clasical energy recovery ventilator (see the picture).

Simultanously with the ventilation of saturated air to the atmosphere, the heat is recovered to the fresh filtrated air. Partial condensation on aluminium core is occurred during the process. Second, output air still reach with the energy is directed to the evaporator of the air-to-water heat pump. There, second heat recovery takes place because energy is transferred to the refrigerant of the heat pump. Overall system efficiency of the double heat recovery system is up to 80%. Last but not least, there is another equally important function of the system. It is automatic control of set moisture level of the drying air inside the dryer, as a prerequisite for having a succesful monitoring of drying process.